Our Brochure

Want to learn more?

Other than all the expected product information, our brochures also contain information on how the systems maximise rumen performance and decrease pasture consumption.

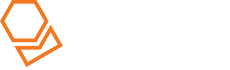

- All the features of the newly released Heavy Duty Range

- How the little and often system increases production

- What is creep feeding and why its returns are so high

- An on-farm trial showing great returns

- Prices and distribution depots

Click images on the right to download

Our Documents

Livestock Feeders User Manual

Everything you need to know about setting up, using the feeders and managing stock.

Consumption Log

A simple table to keep track of and calculate feed consumption.