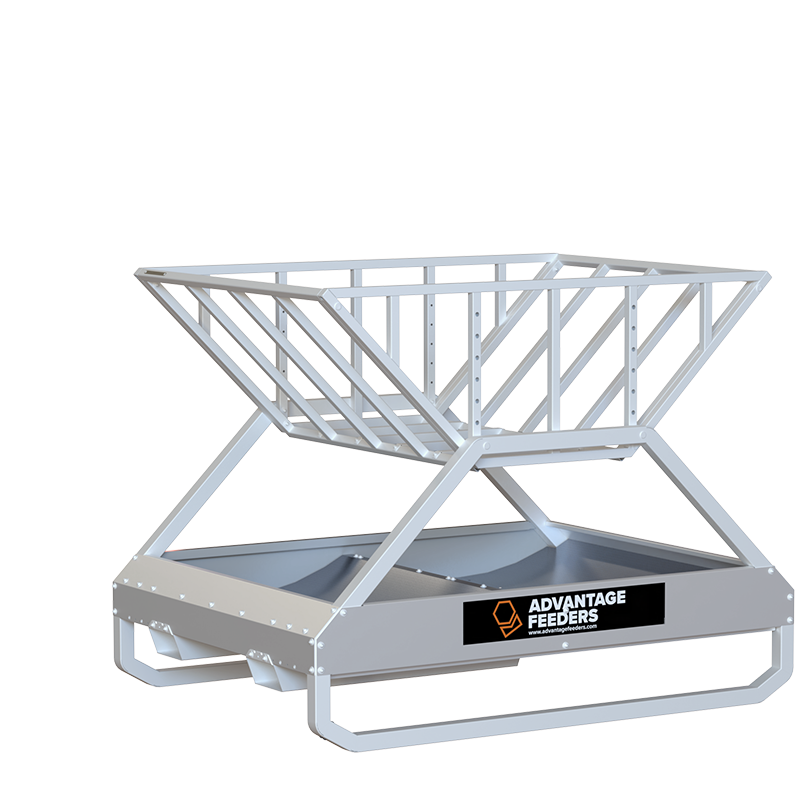

Our Products

Please note all our products come flat-packed

All prices are excluding GST

Creep Feeding

CREEP PANELS

Hay Feeders

Accessories

Extended Warranty

The warranty on all Advantage Feeders products is 2 years. The warranty ensures the products are “fit for purpose”.

The definition of “fit for purpose” relates directly to the feeders ongoing ability to:

– store, distribute and keep feed in the hopper dry from rain

– provide structural integrity without any manufacturer defects

If goods are found to be defective, Advantage Feeders will:

– complete an initial assessment of the damage type and parts required for the repair

– repair or replace the affected parts only

To make a claim, please call 09 280 9597 to start the process.

Free Freight

Pricing includes freight to your most conveniently located Advantage Feeders delivery depot.

For delivery to other locations we have a network of freight providers who can provide delivery to anywhere in New Zealand at reasonable rates.

Our Sales Managers can provide you with a quote for freight to your location.